Factory

24 Hours Operational Plant Spreaded over 32,000 Sq. Ft, Plant in Compliance to ISO 9001:2015 / ISO 14001:2015 / ISO 45001:2015, More than 100 Motivated Team Members

Reception and Office

Reception: Rappid front office is well maintained to Serve visitors by greeting, welcoming, and directing them appropriately. Notifies company personnel of visitor arrival. Maintains security and telecommunications system. Informs visitors by answering or referring inquiries.

Office:

All the amenities and facilities are provided for the health, safety, welfare and personal hygiene needs of employees.

Design & Development

As all product meant for highly critical and dangerous services and applications, all products of “RAPPID VALVES” are manufactured following strict international standards in use by our user industry all over the world, such as ISO,API,NACE,ASME,ASTM,MSS-SP,BSEN amongst others. Our Engineering Team consistently monitors updates to all these standards and incorporates any applicable changes that affect design ,regulation and performance of our products. Our designs are made using the most advanced technology available today and tools such as Solidworks ,Autocad , Ansys, UgNx system Programs to ensure proper and effective long term performance of our products in use. From conception to calculation to detail drawing for manufacturer- the entire chain of CAD to Cam, RAPID VALVES is leader in development of new products that meets the need of an end –use industry.

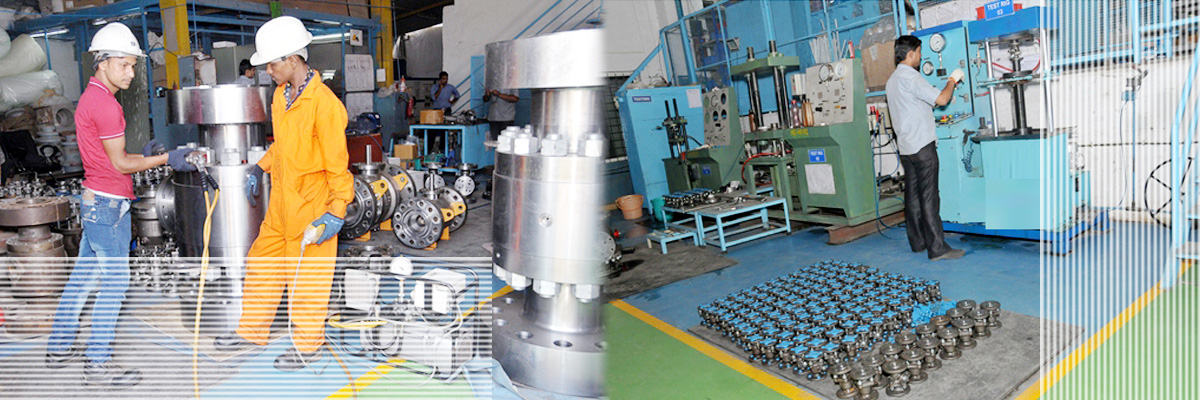

Machinery

Rappid manufacturing focuses on technology. It includes the manufacturing of high quality Industrial Valves. Manufacturing engineering, or the manufacturing process, are the steps through which our raw materials are transformed into a final product. Rappid manufacturing process begins with the product design, and materials specification from which the quality product is made. The in-house machining facility has the capabilities to process a wide range of valve components in different materials such as carbon steel, alloy steel, stainless steel, duplex and super duplex stainless steel, titanium, nickel alloys, aluminum bronzes etc. Rappid Valves’ machining expertise is built up over many years and we have been adding newer and more advanced machineries continuously. The CNC machining capabilities have been powered by Computer aided Manufacturing (CAM) as a result Rappid Valves continuous endeavor for creating the state of art machining facility.

Assembly

Our Assembly Shop has fully qualified employees and Supervising Engineers working to Rappid Valves procedures to guarantee quality products assembled flawlessly to ensure that the products reach the customer without any defects.

Testing

Our Quality Control System in manufacturing process to assure product for best performs to the various industry. In process 100%Inspection of all parts for dimensional accuracy All product are fully traceable to material heat & Identification numbers Hydro Test & Pneumatic test carried out 100% as per applicable test Pressure

Painting

A Negative Pressure Paint Booth and humidity controlled ovens, Rappid Valves has an in-house painting capability to meet a wide spectrum of customer specifications ranging from single coat systems to typically complex and critical multi-coat epoxy and polyurethane systems for offshore environments.

Laser Marking & Packing

Marking:

All our valves are marked in accordance with MSS SP 25, Standard Marking System for Valves, and other specific customer requirements.

Tagging:

All the Valves have tag numbers stamped on a high quality Stainless Steel 316 tag and attached to the valve with suitable Stainless Steel or Monel wire or embossed stainless steel rivets.

Packing:

Rappid Valves responsibility is to ensure that all materials and equipment are properly packed for its intended mode of transport. Machined surfaces are protected with wood and sealed against corrosion. A detailed packing list is fixed in a waterproof envelope outside, and inside the box/package. The packing list strictly follows the format required by the customer.

Warehouse and Store

Rappid Valves is using ERP system & all the items are stored at one place with ERP codes. Materials are received by & issued from one store through ERP system & is ideal from control & traceability point of view.